5 Terms Explained: Digital Manufacturing and the Industrial Internet of Things

The Industrial Internet of Things has many names. So many, in fact, that figuring out exactly what these names mean has become almost impossible. Where does the industrial internet end, and digital manufacturing begin? What is the difference between Industrie 4.0 and the Internet of Things? And where does Lean Manufacturing fit into all this?

In the first of a series digging deeper into these terms (and the questions surrounding them), below are the five information technology terms most common to the manufacturing industry, and what they mean.

What is Digital Manufacturing?

Digital manufacturing, and digital transformation, is about building a technology foundation that allows an organization to innovate, keep up with change and prepare for future business needs. Cisco defines digital transformation as:

“…the application of technology to build new business models, processes, software, and systems that results in more profitable revenue, greater competitive advantage, and higher efficiency. Businesses achieve this by transforming business models, creating new customer experiences, and securing everything.”

For manufacturers, digitizing operations means utilizing a secure IT network that increases factory uptime, enables mass customization, reduces new product introduction cycles, and lays the foundation for future optimization and technology projects.

What is the Internet of Things?

The Internet of Things (IoT) is the connection of people, processes, data and things over an IT network, such as (and including) the internet. For businesses, the IoT is at the centre of the merger of Information Technology (IT) and Operational Technology (OT) as data is collected to gain insights, optimize processes and create opportunities.

Here’s a practical example. A local transit agency has an app that offers real-time updates on when their bus arrives at your stop. This is made possible by sensors and other technologies on the bus that transmit location data over Wi-Fi to the agency’s data centre. This makes the bus a ‘node’ on the agency’s IT network – and thus part of the Internet of Things. But data alone isn’t where the value of the Internet of Things lies – it’s what that transit agency can now do with that information to offer better service (real-time updates), better maintenance (by knowing exactly how far the bus has travelled, and over what roads), and better resource management (by assessing data from multiple routes to identify overlaps and opportunities).

What is the Industrial Internet of Things?

The Industrial Internet of Things (IIoT) is the extension of the IoT into industrial environments. These environments require specialized products and solutions that have been ‘ruggedized’ to operate in extreme situations. They also typically require customization as many legacy infrastructure technologies (think: production line equipment) still run on disparate communication protocols.

The IoT and IIoT create incredible business opportunities because efficiencies are discovered and enhanced productivity is realized when IT and OT data comes together. For manufacturers this translates to improved sustainability, less downtime, and more profitability across the factory floor.

What is Industrie 4.0?

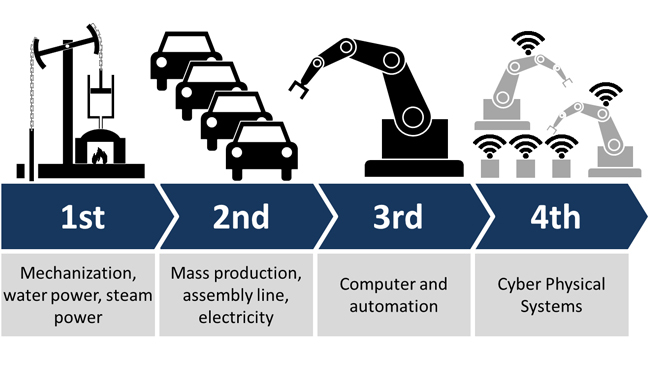

Industrie 4.0 (or Industry 4.0) is a term coined by the German government. It classifies each period of manufacturing revolution by a transformational technology. Industrie 1.0 marked the introduction of steam and water power. Mass production and the assembly line was 2.0, the introduction of automation was 3.0. What sets Industrie 4.0 apart is the new combination of cyber-physical technologies it encompasses: software, sensors, processors, and information and communications technology (ICT). If you are wondering how the IIoT and Industrie 4.0 relate, IIoT solutions are part of the cyber-physical technologies that define the 4th Industrial Revolution.

What sets Industrie 4.0 apart is the new combination of cyber-physical technologies it encompasses: software, sensors, processors, and information and communications technology (ICT). If you are wondering how the IIoT and Industrie 4.0 relate, IIoT solutions are part of the cyber-physical technologies that define the 4th Industrial Revolution.

Or, think of it this way: If Industrie 4.0 was a BLT, the IIoT would be the bacon.

What is Lean Manufacturing?

Lean Manufacturing is a systematic method for the elimination of waste from the manufacturing process. IIoT solutions are a key enabler of Lean Manufacturing by optimizing processes and finding opportunities to eliminate waste. IIoT and Industrie 4.0 are not synonyms for Lean Manufacturing, but rather components of it.

Do you have questions about any of these terms? Leave a comment.

To learn more about the industrial internet, download our free eBook. And if you’re ready to take the next step, find out what the network of the future can do for your business now.

Tags:

1 Comments